Heatrotherm’s coreless induction furnaces offer superior performance & outstanding durability for all your melt shop needs regardless of the size of your foundry. We offer a variety of smaller induction furnaces to meet the demanding require of investment caster.

Induction Billet Heaters designed to through heat cut billets of assorted cross sections uniformly to the forging temperatures as required by application.

The Heatrotherm brand is able to provide the forgers with ultimate induction Long bar & End bar heating system that meets the ever-increasing demands for efficiency and high quality forging products.

Heatrotherm provides flexible quench and temper solutions to match customer production needs in various heat treating applications, such as; scan, single-shot, lift/rotate, pick & place, rotary index and linear transfer.

When forming or swaging tube or pipe, the annealing and / or stress relieving processes enhance your product properties by removing the residual stresses associated with these processes.

By heating or cooling one component before assembly and allowing it to return to the ambient temperature after assembly, the phenomenon of thermal expansion makes a joint.

We are expertise in Coating system for pipes and Re-bars (Construction bars). The energy efficient application of induction heat reduces overall manufacturing costs for production.

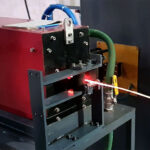

Our metallurgical, technical and product expertise assure reliable and efficient performance when dealing with customized heating and specialized heat treating applications like Brazing & Soldering, Titanium Heating, and Smaller Susceptor heating.

Heatrotherm builds total process systems for cable and wire industries, including heat treating, annealing, softening & coating systems. These all are based on reliable and cost effective induction heating technology.

Induction Angle Heating prior to bending for Power Transmission Towers, Angle Sizes : 45 x 45 x 5 mm to 250 x 250 x 32 mm Length : 6 to 12 mtr.

Heatrotherm is leading manufacturer of Induction Melting & Heating Systems with the worldwide proven Voltage fed series inverter technology.

Our Induction Melting & Heating Systems solution has improved the efficiency and effectiveness in existing or new industrial heating process.

Plot No. 61, Shiv Prerna Industrial Park, Kamod – Pirana Road, Near Ode Village, Paldi Kankaj, Ahmedabad – 382425

Visit Us at Hall No. -2A | Stall No. -B118

Venue : BIEC (Bangalore International Exhibition Centre) India.