Our induction furnace systems have the fastest melt rates from cold charge to pouring temperature, we have an extensive range of induction furnace. The high frequency magnetic field used to stir the hot metal, ensuring of the metal & result in homogenous mixture of alloys.

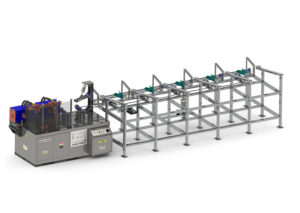

Our Medium-Low Frequency Billet Heater is designed for inductive heating of steel billets with a circular or square cross-section up to forging temperatures. The heaters consist of three modules – feeding, heating and output.

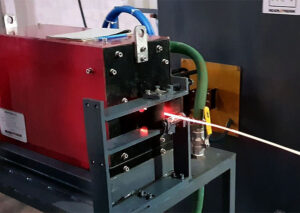

Induction Heat Treatment Systems Induction heating technology is particularily advantageous for spot and surface hardening parts comprised of hardenable materials, because it is possible to attain a high specific power output of many kW per cm2 of surface area of the heated piece, and this takes advantage of what is called the “skin effect.“

The Heatrotherm brand is able to provide the forgers with ultimate induction Long bar & End bar heating system that meets the ever-increasing demands for efficiency and high quality forging products.

End Bar Heaters are practically in field for UPSETTING of components like, U-Bolt, Rear End Piece, Spindle, ‘S’- CAM Shaft, Tube Shaft, Male Shaft, I-Bolt, Leaf Spring, Fasteners, Nut Bolt, RA Shaft, STUB Shaft, Agricultural Products.

Heatrotherm manufacturers systems to pre-heat metal components between 150˚C and 300˚C, causing them to expand and allowing for the insertion or removal of another component. Systems can be manually loaded or can be completely automated with part placement, insertion with cool down included.

Heatrotherm offers a variety of induction heating systems for the pipe and tube industry. When forming or swaging tube or pipe, the annealing and / or stress relieving processes enhance your product properties by removing the residual stresses associated with these processes.

Heatrotherm can design, supply and manufacture complete fixed and portable coating systems for both on and offshore installations. We have expertise in Coating system for pipes and Re-bars (Construction bars).

Induction Angle Heating prior to bending for Power Transmission Towers, Angle Sizes : 45 x 45 x 5 mm to 250 x 250 x 32 mm Length : 6 to 12 mtr.

Sandwich / Capsule brazing is the advancement of induction heating technology in the field of the cookware industry. It has a modular design with the highest flexibility. It provides homogenous heat distribution throughout the susceptor plate. The equipment is applicable to various sizes of cookware. It provides a simple and consistent working process.

Our metallurgical, technical and product expertise assure reliable and efficient performance when dealing with customized heating and specialized heat treating applications like Brazing & Soldering, Titanium Heating, and Smaller Susceptor heating

Heatrotherm builds total process systems for cable and wire industries, including heat treating, annealing, softening & coating systems. All our products for Induction Wire & Strip Heating are based on reliable and cost effective induction heating technology.

Heatrotherm is leading manufacturer of Induction Melting & Heating Systems with the worldwide proven Voltage fed series inverter technology.

Our Induction Melting & Heating Systems solution has improved the efficiency and effectiveness in existing or new industrial heating process.

Plot No. 61, Shiv Prerna Industrial Park, Kamod – Pirana Road, Near Ode Village, Paldi Kankaj, Ahmedabad – 382425